Address: No. 90 Huadong Road, High tech Zone, Qingdao City, Shandong Province, China

E-mail: sainsgas@sainsgas.com

Tel: 18563963366

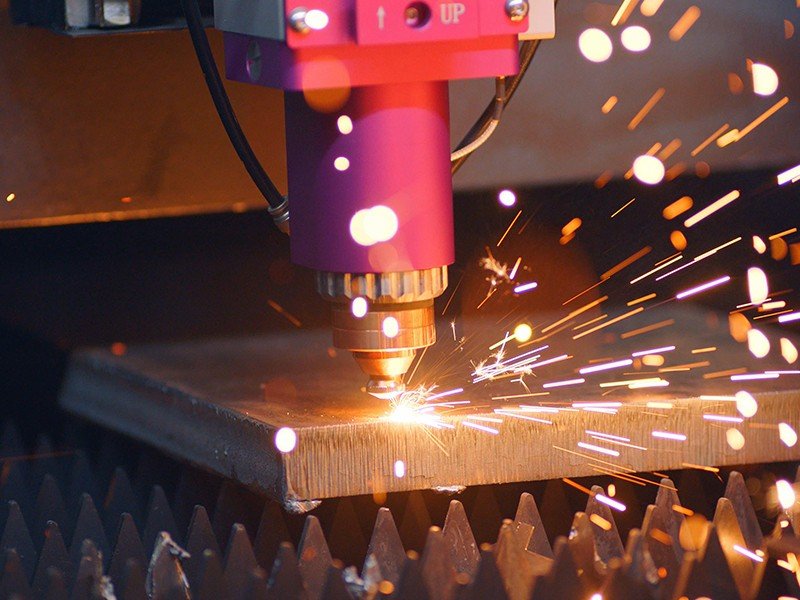

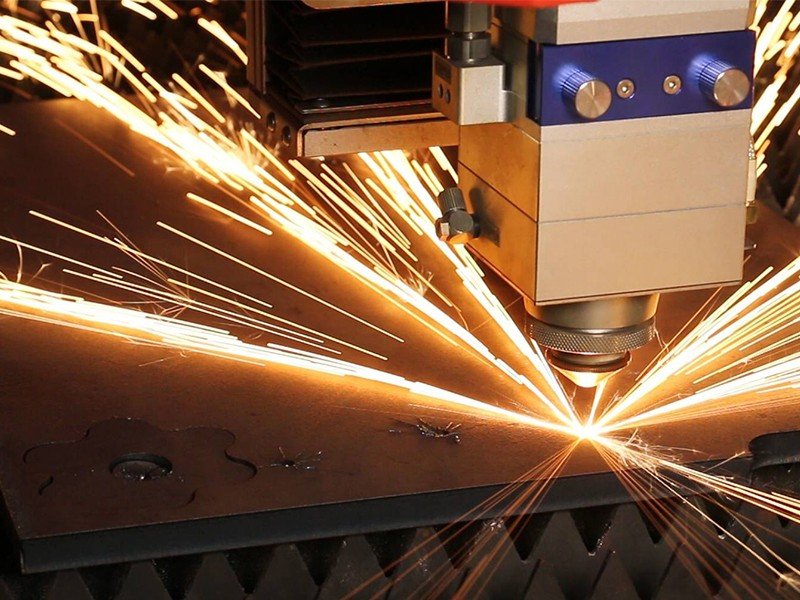

Cutting and welding are the most common methods of metal processing, and are also the most common gas application directions.

For cutting, laser cutting machines, flame cutting, plasma cutting, and fine plasma cutting use different gases. Laser cutting requires high-pressure and high-purity nitrogen as a gas source. Flame cutting and plasma cutting can choose oxygen, acetylene, nitrogen, hydrogen, methane, argon, helium, carbon dioxide and other gases or mixed gases according to different materials and thicknesses.

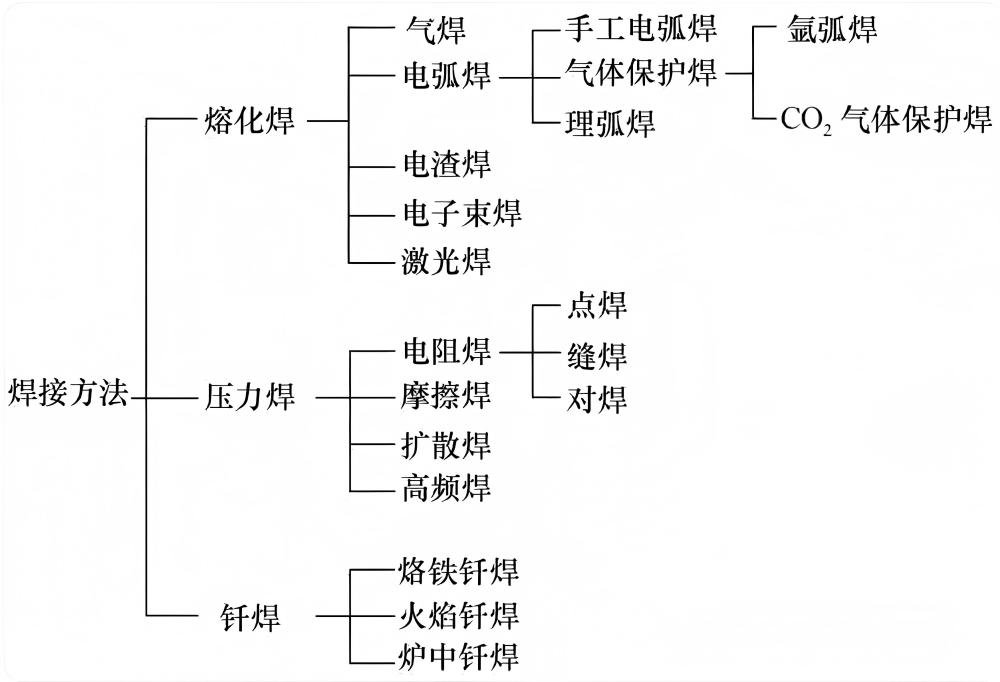

For welding, there are many methods, and many methods are inseparable from gas.

TIG and MIG welding use inert gas argon or helium for shielded welding, which is also commonly known as argon arc welding.

MAG welding uses a mixture of argon and carbon dioxide for shielded welding, commonly known as two-shield welding. Nitrogen is used for brazing protective atmosphere.

How to use these gases correctly and effectively in metal cutting and welding to reduce costs and improve product quality? The three-factor gas team is experienced and has many cases.

Three-factor Gas Company focuses on "gas application solutions", integrating scientific research, design, production, sales, engineering and services. It has advanced technology, rich experience and efficient team in gas application. "Good gas, good luck", three-factor gas helps your company reduce costs, increase efficiency and improve quality. Contact us to get your product gas solution